The global medical equipment maintenance market was valued at $35.3 billion US in 2020 and is set to increase at a compound annual growth rate of 7.9% from now until 2027. This is an area of increased demand as the population ages and health concerns rise.

One of the most common use cases where ProntoForms is used within the medical device manufacturing industry is preventive maintenance. Keeping your medical devices up and running is a daunting task given they are extremely complex, highly sophisticated, and expensive assets. Preventive maintenance ensures there’s no costly downtime from both a healthcare and financial standpoint. Failure is not an option.

How ProntoForms helps

Using ProntoForms to digitally transform your preventive maintenance activities yields many benefits, helping medical device manufacturers:

- Ensure patient safety

- Increase efficiency

- Improve processes

- Cure compliance risks

- Increase asset lifespan

- Reduce costs

- Mitigate business risks

While this is an impressive list of benefits to read, we know you want to hear about the results to be gained. Read on to discover how we helped a Fortune 500 medical device manufacturer advance their preventive maintenance efforts.

Medical device manufacturing preventive maintenance use case

The Fortune 500 medical device manufacturer turned to us to help with several challenges they were experiencing with their preventive maintenance process. The issues they faced included:

- Stringent compliance requirements. The company was required to comply with complex regulatory requirements established by different authorities across various countries.

- Complex, multi-step process. Each device has multi-step standard operating processes that field service technicians are required to recognize and follow. The company wanted to standardize its comprehensive checklists for use by techs of any skill level.

- Inflexible systems. The manufacturer’s field services operation still relied on manual processes such as paper or semi-digitized forms, resulting in potential errors and improper version control.

- Lacked robust, meaningful analytics. The company needed the right analytics and reporting tools to gain actionable insights.

- Scalability. With over 20,000 employees spread across 70 countries, the organization needed a scalable solution it could rapidly deploy across various geographies.

ProntoForms is an effective solution for preventive maintenance

The manufacturer began using ProntoForms in 2020, and by the beginning of 2021, it was adopted by 980 users by its EDS Group in North America, Europe, and Asia. The solution has been used by its field services engineers, supervisors, managers, and business groups.

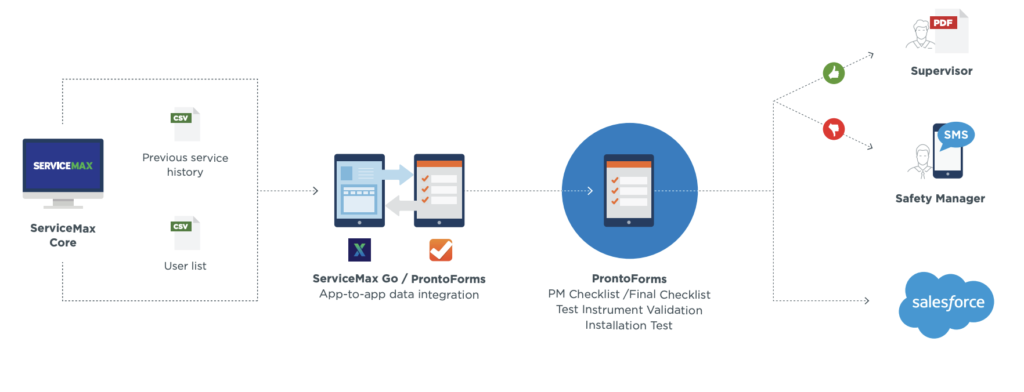

ProntoForms fits into the company’s existing workflow and benefits from tight integration with its existing field service management system and work order management system. This image shows a simplified workflow and how ProntoForms is positioned to take advantage of the company’s existing integrations to enhance their field service capabilities.

Results gained by using ProntoForms for preventive maintenance

With ProntoForms, the Fortune 500 medical device manufacturer has improved its field services operations specifically for preventive maintenance and inspection. They generated positive business outcomes in several key areas:

- Cost saving through efficiency. ProntoForms helped the company’s field services team become more efficient by eliminating repeat work, saving over 15 minutes per case or approximately $700K. Better preventive maintenance means the improved extension of asset lifetime and service call efficiency.

- Reduced mistakes/data integrity. The company now relies upon mistake-proof data entry and can easily find gaps in their processes. The organization can deploy calibrated tools into their process while ensuring the forms are designed according to the exact steps and validation process used. Features such as the automatic geo-stamping feature mean they can maintain data traceability easily.

- Speedy deployment. Using ProntoForms’ visual, low-code solution, the company has built and deployed over 99 unique forms, including 20 which are related to preventive maintenance. So far, there have been over 7,000 unique submissions, of which nearly 2,000 are directly related to preventative maintenance and testing.

- Compliance and audits. ProntoForms’ built-in security features help the organization meet changing regulatory needs. It’s easy to meet traceability, accountability, and data integrity standards needed to offer aftermarket services.

- Faster quotes for better CSAT. Before ProntoForms, the team would spend time on emails and calls back and forth to populate Excel, Word, or PDF forms. For example, the company had a list of corporate accounts in an Excel spreadsheet which was not tracked in their system of record and was labor-intensive for inside sales to maintain. With ProntoForms, the field services team now gets professional forms that require a minimum set of data to be closed.

- Unified use cases. While the organization was using ProntoForms to modernize their preventive maintenance workflow, it’s not the only use case they are using ProntoForms for. They are also using the solution for installation, repairs, and training. These all work together to streamline their entire field services operation and optimize the workforce. For example, using ProntoForms to train field technicians means they can effortlessly adopt standard operating procedures to complete service work orders in the field without having to learn using multiple tools or processes.

The customer’s perspective on the solution

“The biggest benefit for our field engineers was they didn’t have to enter the data that’s already in ServiceMax because ProntoForms can pull it automatically. In addition, all our service test procedures are now automated, and the data gets automatically sent to a database when a Field Engineer completes their service work. That alone is saving us 15 minutes per case.”

Global systems deployment lead, Fortune 500 medical device manufacturer

Are you wondering how ProntoForms can not only help enhance your preventative maintenance efforts but also support asset inspections, EHS reporting, audits, installation procedures, and more? We’d be happy to discuss your specific use case and demonstrate how our best-in-field mobile app solution will transform your business.

If you’re new to our solution, start a trial today, or reach out for a quick demo.

If you’re an existing customer, connect with your Account Executive to uncover any additional use cases you can use our product for to maximize your ProntoForms investment.